Cady Enterprise has the software to design and manufacture your replacement labyrinth seals.

Choosing the correct software is just as important as choosing the correct machines and cutting tools. We based our choices on the usability of the software as well as compatibility with industry standard file formats. Once software is purchased, it is always kept current to latest version. This ensures we always have the newest software enhancements and the best file format compatibility.

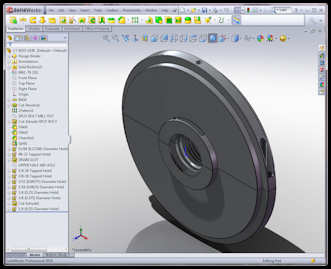

We use SolidWorks design software to efficiently and accurately transform part samples into 3D solids. SolidWorks allows us to also accept many file formats from vendors when necessary. Once the model is completed and verified for accuracy and design intent the information can easily be shared with our CAM system. This greatly reduces errors and speeds up machine programming when compared to recreating geometry in the CAM system. SolidWorks also preforms design checks to ensure assemblies fit together the first time.

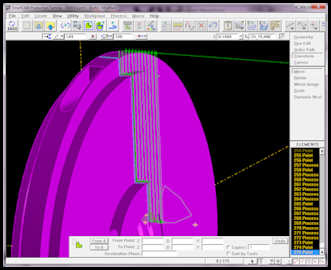

We use SmartCAM to generate the necessary code for our CNC machines. SmartCAM allows us to import information from many industry standard formats. When deciding on software for programming our CNC machines, we had some very strict requirements. Most CAM software can produce the required code to produce parts with standard features. When features are not so standard, we wanted absolute control over the toolpath. We also needed the ability to customize the software to meet our specific needs.